Get Support

123-456-789-10

Our Recommend

Product Categories

Focus on product quality, stability, reliability, economy and performance ALWAYS & dedicated service at all time.

Supply to the industry of Automotive, Railway, Slurry Pump, Bearing, Gear, Heavy Truck, Mining Machine, Wind Power & Metallurgy Roll, etc. Widely exported to more than 20 countries

Mintek Abrasives & Tools, the professional manufacturer for abrasives and tools

Companies specializing in the production line can really adapt to a variety of requirements to meet different customer requirements.

Our Recommend

HOT PRODUCTS

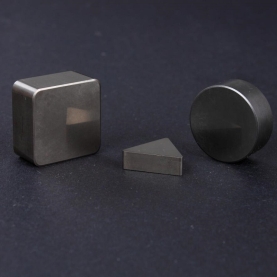

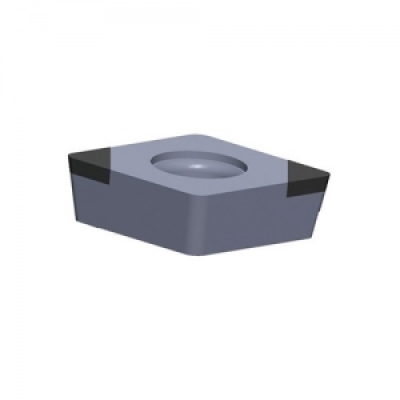

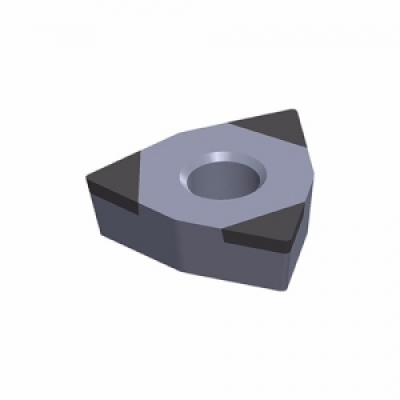

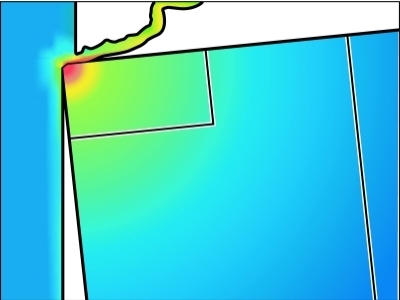

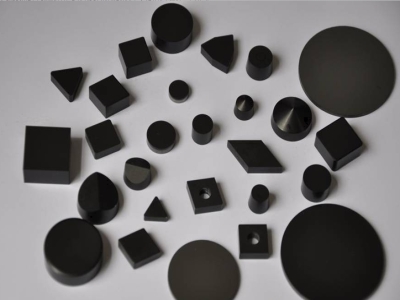

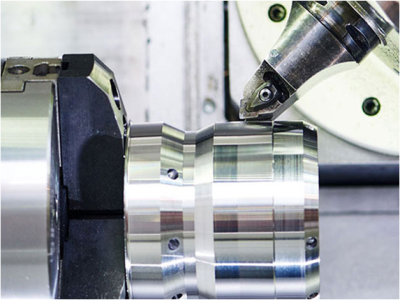

CBN inserts/PCBN inserts/solid CBN inserts/CBN powder of Mintek Abrasives & Tools which is the professional manufacturer for abrasives and tools, widely used in cutting and processing of cast iron and high alloy casting steel. Because the hardness of PCBN cutting tool is second only to diamond, with strong wear resistance, with chemical inertness of do not react with iron group metals at high temperature, so it is mainly used for machining of high hardness material and difficult-to-machine materials, such as: machining of gray cast iron, hardened steel, high alloy wear resistant cast iron, high temperature alloy, high speed steel, surface spray welding materials, sintered metal materials .etc.

About Us

Mintek Abrasives & Tools which is the professional manufacturer for abrasives and tools was founded base the reasearcher who began his reasearch and development in year 2006 would like to show the excellent performance and tool life of the CBN inserts/solid CBN inserts/PCBN inserts for cutting, turning or milling cast iron and steel workpieces like brake disc, roll, gear, cylinder block, pumps etc. As a cutting tools provider with strong and faithful support, we have grown up to deliver good quality products to use in the Metal Machining Industry.

Mainly Produce & Supply :

Solid CBN Inserts

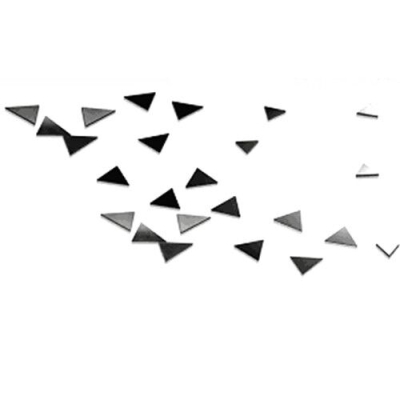

Solid CBN corner inserts

Tipped PCBN inserts

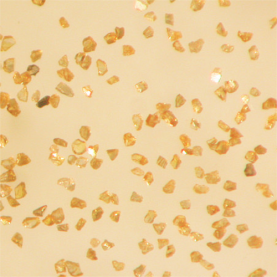

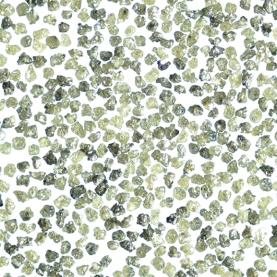

CBN powder

Diamond Powder

CVD Diamond products

For more details please contact us at

info@mintektools.com

Application

PCBN inserts/CBN inserts is second only to diamond and has strong wear resistance. It is chemically inert without reacting with iron metal at high temperature. Therefore, it is mainly used for cutting high hardness materials and difficult-to-cut materials, such as hardened steel, Cutting of difficult-to-machine materials such as high-alloy wear-resistant cast iron, high-temperature alloy, high-speed steel, surface spray-welded materials, and sintered metal materials.

●Roughing

●Heavy load Roughing

●Semi-finishing

●Finishing

●Turning Instead of grinding

●Milling Instead of grinding

Applied industries of MinTek CBN inserts as below,

Roll, Auto parts, Railway Industry, Mining & Machinery Industry, Slurry Pump Industry, Gear & Bearing Industry, Air-Conditioning Compressor Industry, Engineering Machinery, Machine Tool, Die, Wind Power industry, etc.

Plastic & Packing

Rough turning Roll ExcircleWorkpiece: Roll

Material: TC Roll

(Tungsten Carbide Roll)

Hardness: HSD90

Inserts: RNMN190700/RNMN120400 RCMX190700/RCMX250700

Grade: MTN-60

Cutting parameter :Vc=50m/min, ap=12mm,f = 2mm/r

Our CBN inserts improve the efficiency by 25% and increase the life by 100%.

Food Processing

Workpiece: Brake DrumMachining position: Excircle, Inner bore

Material: HT250

Hardness: HB170-210

Grade: MTN-20, MTN-70, MTN-80

CBN Inserts: SNGN120716

Cutting parameter:vc=160m/min, ap=3mm,f=0.3mm/r;

Mintek CBN inserts improve the efficiency by 30% and increase the life by 60%.

Corrugate & printing

Workpiece: Parts of Slurry PumpMachining position: Outer circle and end surface

Material: High-Cr alloy

Hardness: HRC57

Grade: MTN-20, MTN-60, MTN-80

CBN inserts: RNGN120400

Cutting parameter: Vc=55m/min, ap=2-3mm, f = 0.3mm

Mintek CBN inserts improve the efficiency by 40% and increase the life by 100%.

Paper & Tissue

Workpiece: Big Gear( Dia 12m)Machining position: top excircle

Material: 40CrMo

Hardness: HB280-360

Grade: MTN-90

CBN Inserts: SNMN201020

Cutting parameter:Vc=50m/min,f = 0.7mm

Roughing ap=4mm,

Finishing ap=0.5mm,

Machining Time: 2 hours/pc

Mintek CBN inserts improve the efficiency by 6-8 Times, the cost is just 1/6 compared with before.