Get Support

123-456-789-10

Introduction for PCBN inserts

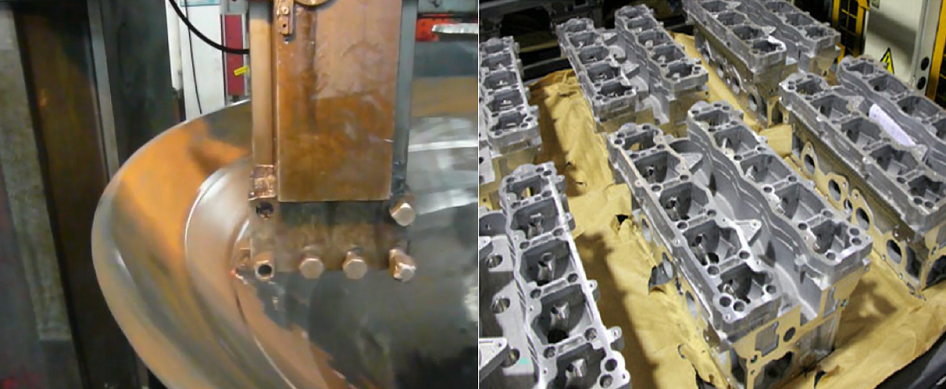

PCBN Inserts is second only to diamond and has strong wear resistance. It is chemically inert without reacting with iron metal at high temperature. Therefore, it is mainly used for cutting high hardness materials and difficult-to-cut materials, such as hardened steel. Cutting of difficult-to-machine materials such as high-alloy wear-resistant cast iron, high-temperature alloy, high speed steel, surface spray-welded materials, and sintered metal materials.

1, Processing cast iron and hardened steel can achieve the effect of grinding by turning. Since the cutting depth is more than ten times larger than the grinding depth, the machining efficiency is high and the surface does not produce burns. If the variable speed sliding gear (20CrMnTi, hardness HRC58-62) is machined by grinding, the cutting efficiency is increased by more than 4 times compared with the original grinding process.

2, Processing high alloy (including tungsten or chromium 18%), wear-resistant cast iron, cutting speed is more than 10 times than hard alloy tools, cutting efficiency is increased by more than 4 times.

3, Processing high cobalt chromium molybdenum corrosion resistant alloy, PCBN cutting speed of 160m/min, is 8 times that of cemented carbide inserts.

4, Processing thermal spray (spray welding) materials, surface spray weldments can not be used for grinding, and the cutting efficiency with carbide tools is extremely low, the use of PCBN inserts can improve processing efficiency, saving processing costs of more than 50%.

PCBN inserts mainly be used in ferrous metal, but could also be used for precision cutting of partially non-ferrous metals and machining of sintered metals with the development of produce technology sometimes.

More information for CBN inserts, kindly feel free mail to mintek999@sina.com at any time.

By: admin

By: admin