Get Support

123-456-789-10

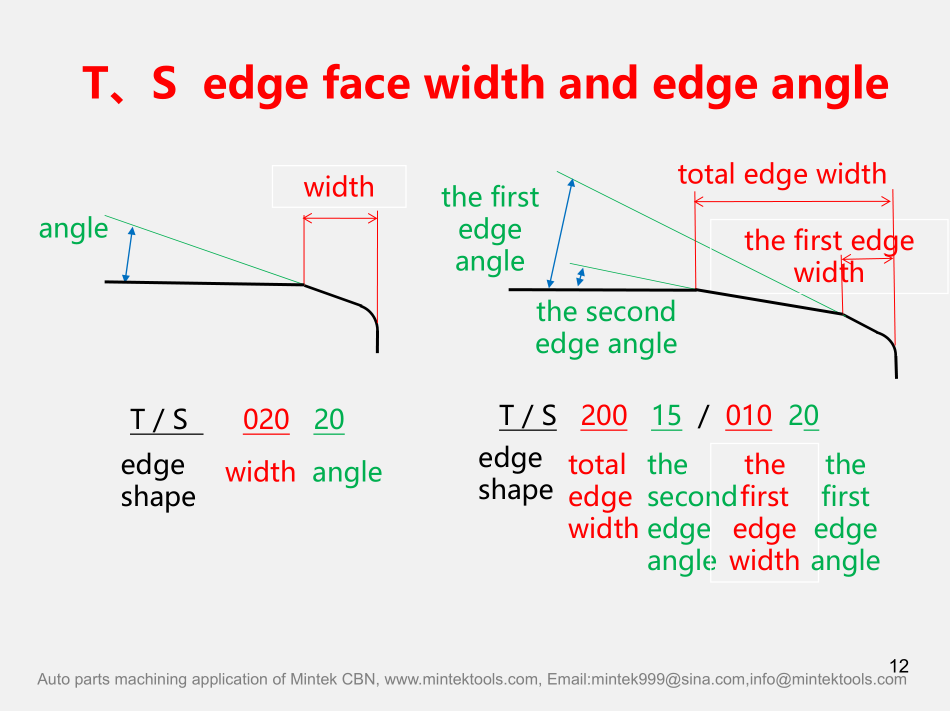

Choice of edge face width and edge face angle on CBN inserts

The shape of the cutting edge for CBN inserts mainly includes edge face land(cutting edge length, cutting edge width),edge face angle, cutting edge R, wiper and other main elements.

Through the analysis of these main elements to understand the relationship between them and cutting performance, we can determine the best cutting edge shape for different processing materials and cutting conditions, so that the performance of the CBN inserts could be best shown.

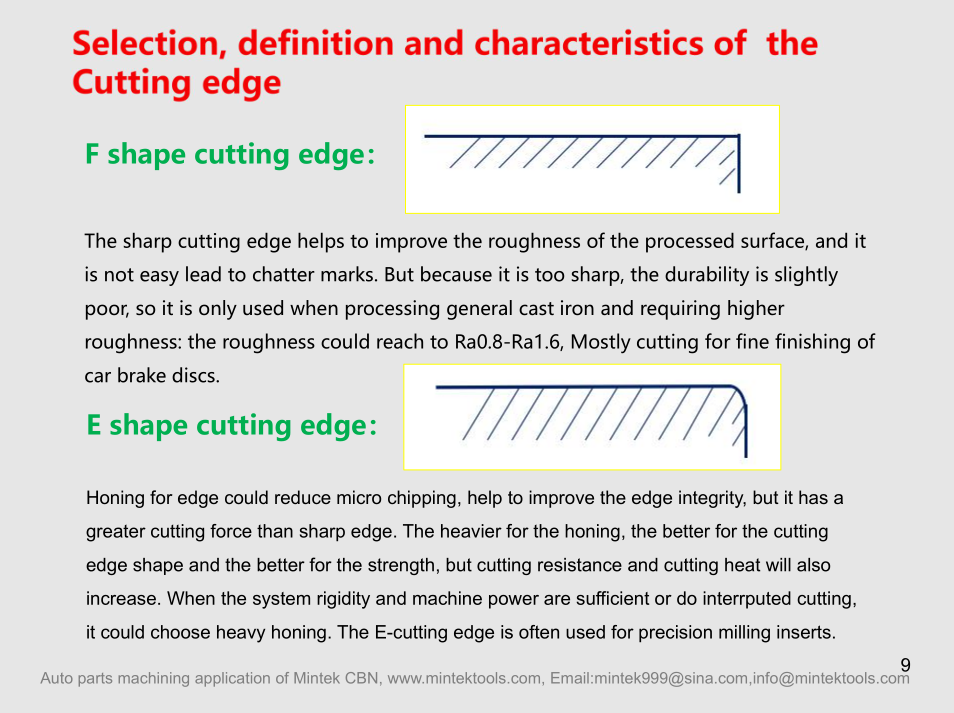

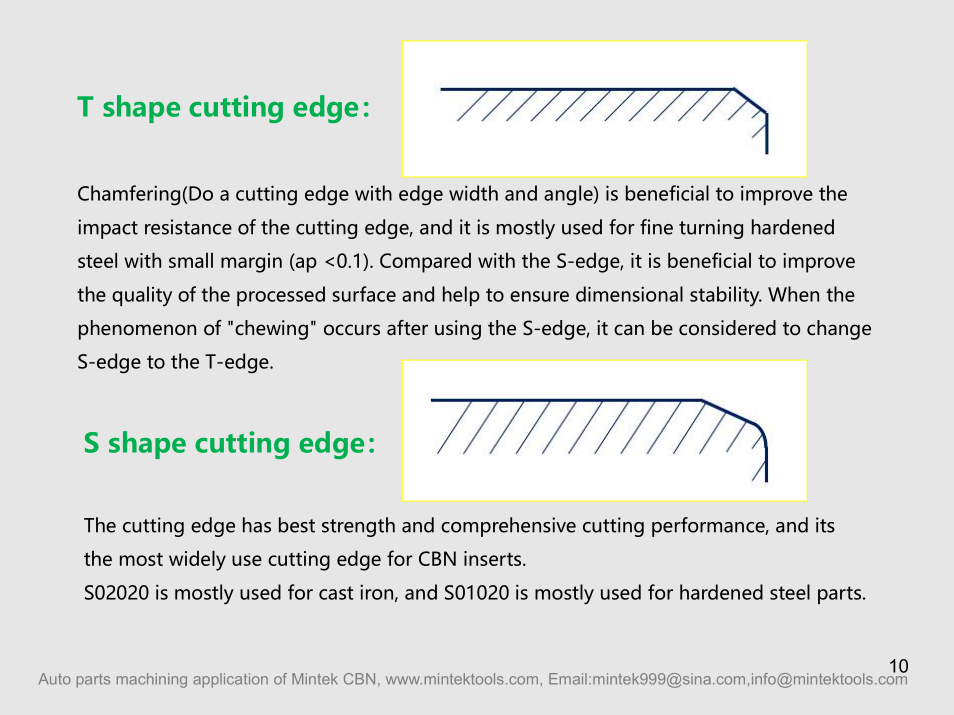

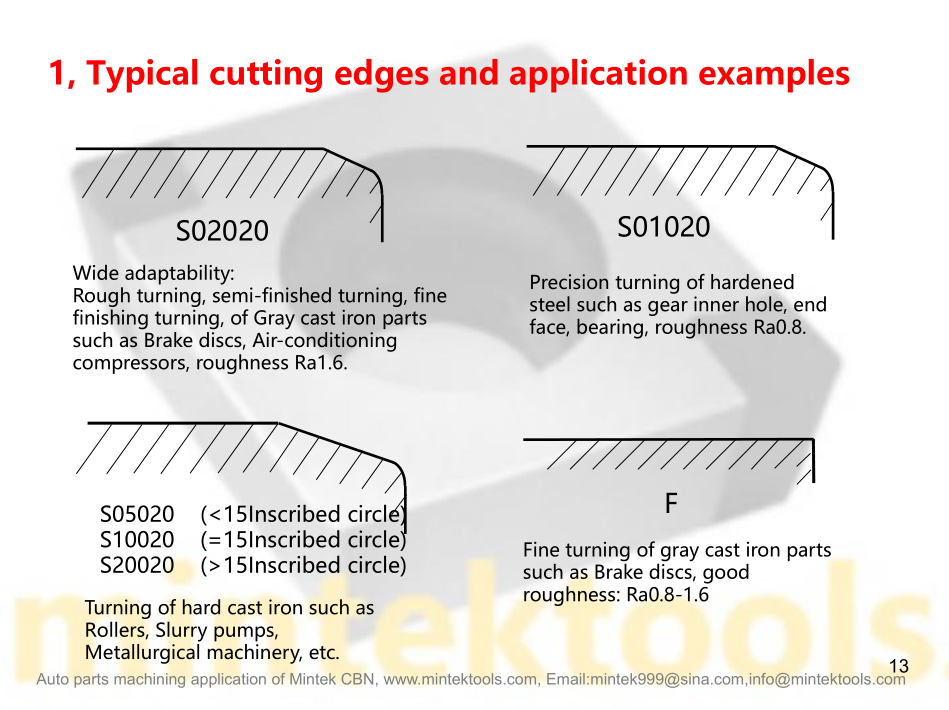

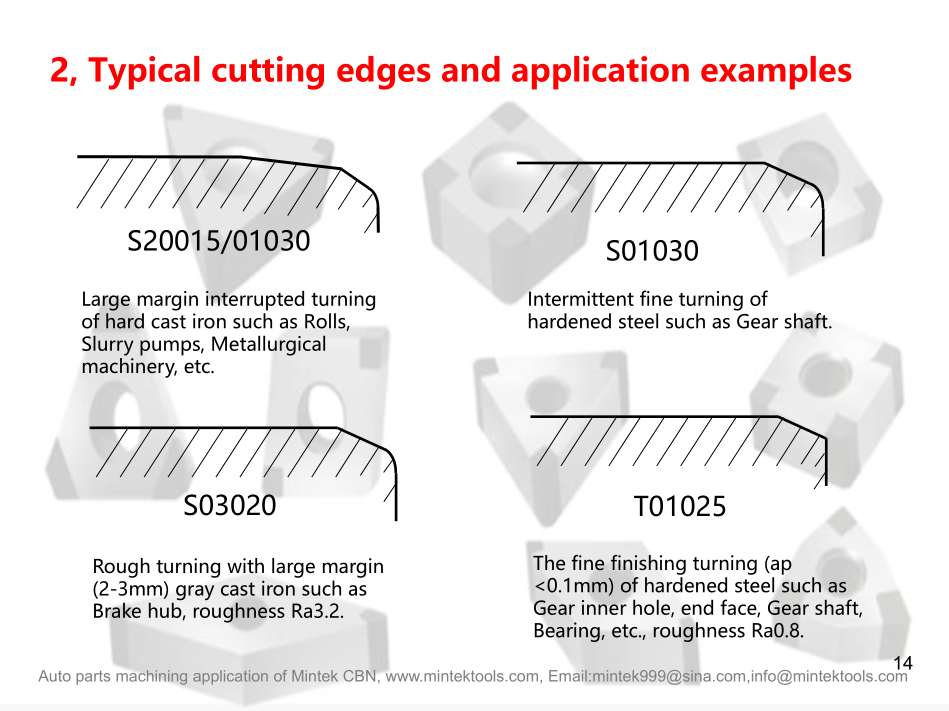

The cutting edges of CBN inserts are divided into four forms: F, E, T, and S

Edge face angle:

The larger the chamfering angle, the better the impact resistance of the cutting edge, but the cutting resistance will increase, which requires higher system rigidity and machine power. 15 ° -25 ° for ordinary cast iron, 20 ° -30 ° for hard cast iron or intermittent cutting, and 20 ° -35 ° for hardened steel.

Edge face width:

The chamfering width is generally less than the feed rate per revolution. 020 is used in cutting cast iron, and 010 is used in cutting hardened steel usually. For large margin and large feed rough turning hard cast iron, it is recommended to use a larger chamfer width and heavy honing combination, such as 050 and 100 are used to obtain better impact resistance and longer life for turning rolls commonly.

Double cutting edges:

It is recommended to use the double chamferring form when turning hard cast iron with large allowances, e.g. S20015/01030, for getting better impact resistance and excellent cutting performance.

|

Major factor |

Cutting edge selection principles and recommendations |

|

|

Materials |

Cast Iron |

Suggest S02020. |

|

Hard Cast Iron |

Suggest S20020、S10020, HS20020、S20015/01030 cutting edges. |

|

|

Hardened steel |

When the ap<0.1mm,f<0.1mm/r , Suggest T01025 0.3mm>ap>0.1mm, Suggest S01020. |

|

|

System rigidity |

The S-type is recommended when the rigidity is good, and the T and F types are available when the rigidity is poor. |

|

|

Workpiece rigidity |

The S- type is recommended when the rigidity is good, and the T and F types are available when the rigidity is poor. |

|

|

Machine power |

When the power is good, the heavy honing edge type can be considered to increase the durability of the CBN inserts. |

|

|

Intermittent cutting |

On Intermittent cutting we could consider increasing the chamfering angle and heavy honing edge type, ordinary |

|

|

Durability |

S-type and heavy-honing cutting edgesc could help improve durability. |

|

|

Roughness |

When the roughness requirements are high, it is recommended to use the F-type or the smoothing edge type. |

|

|

Feed rate per revolution |

Generally, the feed rate * 0.5 |

|

By: admin

By: admin