Get Support

123-456-789-10

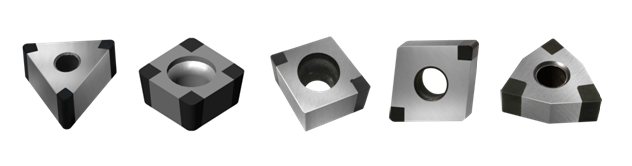

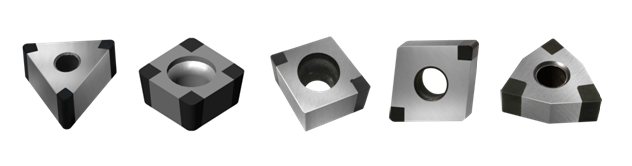

The application features of PCBN inserts

Due to its excellent cutting performance, PCBN inserts material is especially suitable for processing hardened steel with hardness above HRC45, wear-resistant cast iron, heat-resistant alloy above HRC35 and pearlite gray cast iron which is difficult to process under HRC30.

In order to give full play to the superiority of PCBN inserts and achieve satisfactory processing results, in actual processing, it should be considered comprehensively based on machine tools, workpieces and other related specific conditions.

1. In the case of hard cutting, the radial force is very large, which requires the machine tool to have a large power and the machine tool system to have a good rigidity. This can protect the PCBN inserts and obtain satisfactory processing results. When clamping a PCBN inserts, the inserts should be as short as possible to prevent the tool holder from fluttering and deforming, so that the PCBN inserts maintains a good machining state.

2. The strength of the PCBN inserts is lower than that of the cemented carbide inserts. Therefore, in the hard cutting process, the negative rake angle, the large back angle and the negative chamfer are generally used, which is not only beneficial for reinforcing the cutting edge, but also has a good wear resistance.

3. In order to use PCBN inserts well, to stably control the quality of the work piece, it is important to accurately determine the wear resistance of the PCBN inserts. If the tool with severe wear is used all the time, the cutting force and cutting temperature increase, the cutting is not smooth, it is difficult to control the work piece size and indicate the integrity, and even the PCBN inserts wear amount reaches 0.3-0.6mm (minimum when finishing) should be reground. However, re-grinding requires certain equipment and skills. Most factory machines do not have the right conditions. Generally, the re-grinding of PCBN inserts should be done by a professional factory.

4. For workpieces with high hardness and irregularity, PCBN inserts are brittle and be afraid of impact. Cut in and out from the end face of the workpiece, especially when there are slag inclusions on the surface, sand holes, unevenness, the most likely impact, the cutting edge is broken, resulting in reduced durability. Therefore, before using the PCBN inserts, it is best to rough the chill layer once and chamfer the workpiece at the cutting end to reduce the impact of the PCBN inserts.

5. PCBN inserts are not suitable for processing softer ferrous materials.

5. PCBN inserts are not suitable for processing softer ferrous materials.

6. Determine the cutting speed, feed rate and cutting depth to consider production efficiency and processing cost. In general, the cutting speed can be about 2 times higher than that of the cemented carbide tool. The high cutting speed generates large cutting heat, which increases the plasticity of the material to be processed, which is beneficial to control cutting and reduce cutting force.

7. When using PCBN inserts, you can add coolant or not add. If you use coolant, you must fully cool it.

In order to give full play to the superiority of PCBN inserts and achieve satisfactory processing results, in actual processing, it should be considered comprehensively based on machine tools, workpieces and other related specific conditions.

1. In the case of hard cutting, the radial force is very large, which requires the machine tool to have a large power and the machine tool system to have a good rigidity. This can protect the PCBN inserts and obtain satisfactory processing results. When clamping a PCBN inserts, the inserts should be as short as possible to prevent the tool holder from fluttering and deforming, so that the PCBN inserts maintains a good machining state.

2. The strength of the PCBN inserts is lower than that of the cemented carbide inserts. Therefore, in the hard cutting process, the negative rake angle, the large back angle and the negative chamfer are generally used, which is not only beneficial for reinforcing the cutting edge, but also has a good wear resistance.

3. In order to use PCBN inserts well, to stably control the quality of the work piece, it is important to accurately determine the wear resistance of the PCBN inserts. If the tool with severe wear is used all the time, the cutting force and cutting temperature increase, the cutting is not smooth, it is difficult to control the work piece size and indicate the integrity, and even the PCBN inserts wear amount reaches 0.3-0.6mm (minimum when finishing) should be reground. However, re-grinding requires certain equipment and skills. Most factory machines do not have the right conditions. Generally, the re-grinding of PCBN inserts should be done by a professional factory.

4. For workpieces with high hardness and irregularity, PCBN inserts are brittle and be afraid of impact. Cut in and out from the end face of the workpiece, especially when there are slag inclusions on the surface, sand holes, unevenness, the most likely impact, the cutting edge is broken, resulting in reduced durability. Therefore, before using the PCBN inserts, it is best to rough the chill layer once and chamfer the workpiece at the cutting end to reduce the impact of the PCBN inserts.

6. Determine the cutting speed, feed rate and cutting depth to consider production efficiency and processing cost. In general, the cutting speed can be about 2 times higher than that of the cemented carbide tool. The high cutting speed generates large cutting heat, which increases the plasticity of the material to be processed, which is beneficial to control cutting and reduce cutting force.

7. When using PCBN inserts, you can add coolant or not add. If you use coolant, you must fully cool it.

By: admin

By: admin