Get Support

123-456-789-10

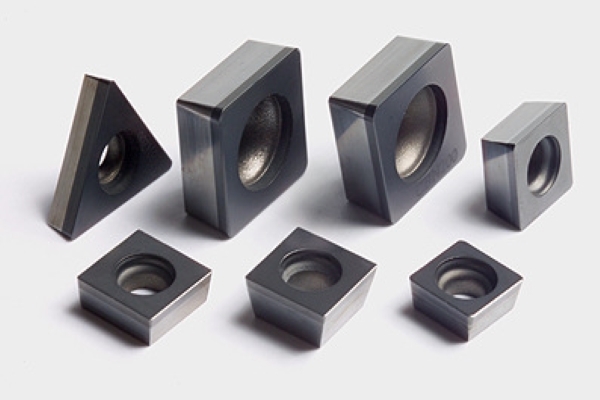

Differences in understanding CBN and PCD inserts or tools

CBN inserts/PCBN inserts mainly processes black high hardness metals(Ferrous metals), such as hardened steel and cast steel (cast iron), which can withstand high temperature (above 1000 degrees) and hardness at 8000 HV. CBN is a good tool material for improving production efficiency and processing difficult-to-cut materials. However, CBN this material is not suitable for processing steels below 45HRC, which is prone to bond wear and cracking.

PCD is mainly used to process non-ferrous metals such as non-ferrous metals. It can sharpen sharp edges and obtain a better processed surface. PCD can generally achieve a finish of Ra0.2, and it is also the material of choice for processing non-metallic new materials. It is highly resistant. Grinding, low friction, hardness can reach 10000HV or more, PCD can cut high hardness products such as hard alloys and industrial ceramics.

Performance characteristics of CBN inserts/PCBN tools/PCBN inserts as below,

- High cutting speed;

- High durability;

- Processing accuracy and surface quality is good;

- High metal removal rate;

- Can replace grinding.

By: admin

By: admin