Get Support

123-456-789-10

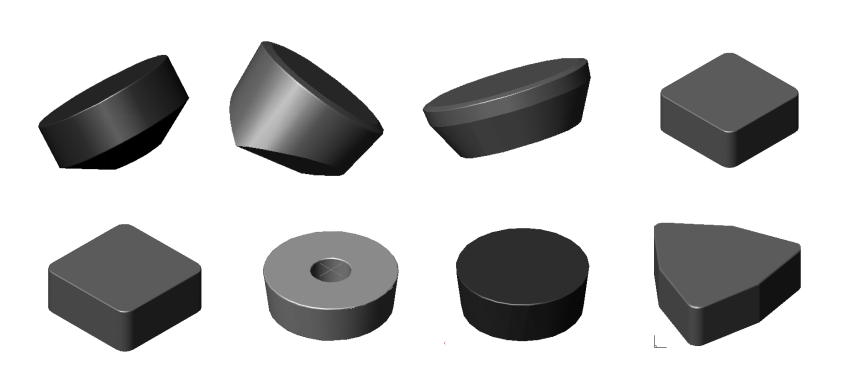

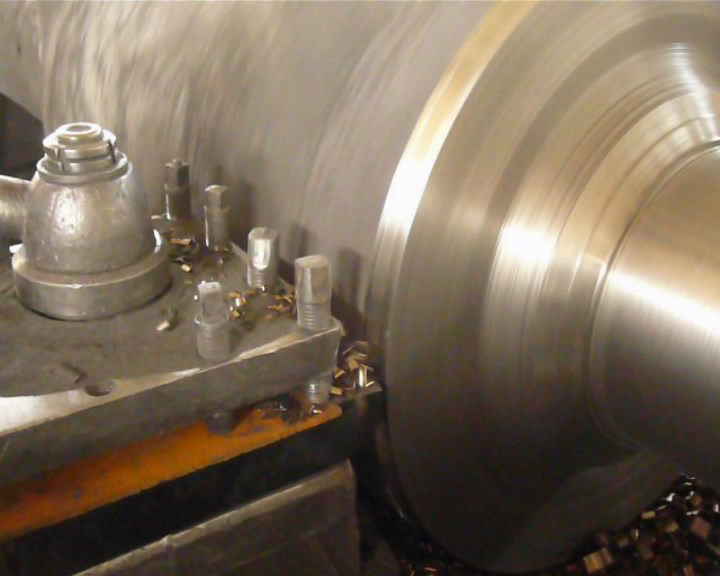

CBN inserts are used in the roll processing industry widely

With the development of science and technology, there has been a major breakthrough in the manufacturing technology of PCBN inserts, which has been in the heavy-duty cutting and intermittent cutting industries, It is widely used in hardened steel, high alloy cast iron, high speed steel, tungsten carbide alloy, and Its also widely used in super hard materials such as nodular cast iron, gray cast iron, high manganese steel and alloy steel.

The application technology of PCBN inserts is constantly maturing, and people's understanding of cubic boron nitride monolithic polycrystalline(PCBN) has undergone important changes.

PCBN inserts/CBN inserts (Here we mean solid CBN inserts) are used in the roll processing industry: (rough turning, finishing turning)

| Roll material | Hardness | Suggestion for cutting parameter | ||

| 1 | Cast High-Cr iron | HSD72-78 | High nickel chrome rough turning High nickel chromium semi-finishing High chromium iron rough turning High chromium iron semi-finishing |

V=15-30m/min ap=3-7mm f=1-2.5mm/r V=20-40m/min ap=4mm f=1.5-2.5mm/r V=10-20m/min ap=3-7mm f=0.50-1.2mm/r V=15-30m/min ap=4mm f=1.5-2.5mm/r |

| 2 | Cast High-Ni-Cr | HSD72-82 | ||

| 3 | Cast HSS | HSD82-90 | Cast HSS | V=5-15m/min ap=3-8mm f=1-2.5mm/r |

| 4 | Cast semi-steel | HSD55-65 | Cast semi-steel | V=30-60m/min ap=4mm f=1.5-2.5mm/r |

| 5 | High carbon semi-steel | HSD65-72 | High carbon semi-steel | V=25-50m/min ap=4mm f=1.5-2.5mm/r |

| 6 | Chilled cast iron | HSD50-70 | Chilled cast iron | V=25-50m/min ap=4mm f=1.5-2.5mm/r |

| 7 | Cast high chrome steel | HSD68-75 | Cast high chrome steel | V=20-45m/min ap=4mm f=1.5-2.5mm/r |

| 8 | Tungsten carbide roller ring | HRA88 | Tungsten carbide roller ring | V=10-15m/min ap=1mm f=0.3-0.7 mm/r |

| 9 | Forging 9Cr2Mo | HSD92-105 | Forging 9Cr2Mo | V=10-25m/min ap=1mm f=0.5-1.2 mm/r |

By: admin

By: admin