Get Support

123-456-789-10

Cutting/Machining/Processing way of CBN Inserts(Solid CBN Inserts, Solid CBN corner inserts, Tipped PCBN inserts)

Cutting/Machining/Processing way of CBN Inserts(Solid CBN Inserts, Solid CBN corner inserts, Tipped PCBN inserts)

●Roughing

●Heavy industry Roughing

●Semi-finishing

●Finishing

●Turning Instead of grinding

●Milling Instead of grinding

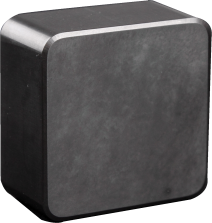

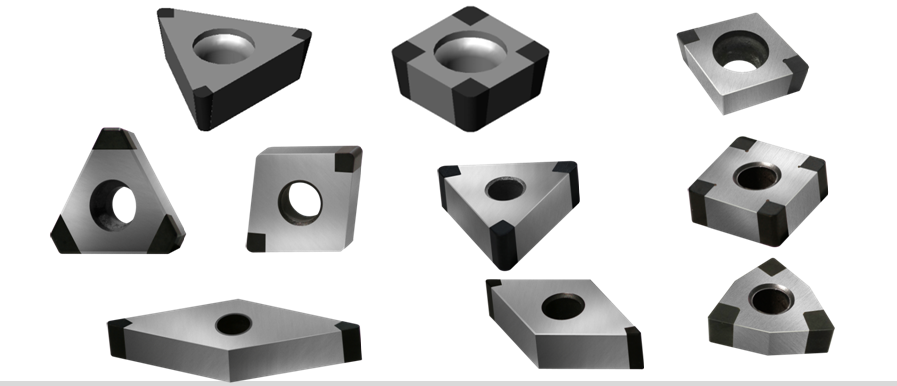

Solid CBN Inserts

- Excellent impact resistance, anti-shock

- Excellent wear resistance, anti-wear-off

- Both surface sides cutting edges could be used in machining

- Big size, the cutting depth could be up to 15mm, excellent impact resistance

- Be suitable for light cutting, it aslo be good at heavy industry, continuous, interrupted and unsteady cutting

- Heavy interrupted and continuous machining/processing/cutting

- It is an important way of CBN inserts application by limiting the cutting temperature, controlling feed rate and cutting speed. If the temperature is controlled at 800-1200 degree, it can effectively improve the impact resistance of CBN inserts.

- When the cutting temperature is low, the feed rate of per revolution should be appropriately reduced. Toughness and strength of the CBN inserts under low temperature, compared with high temperature, will be reduced.

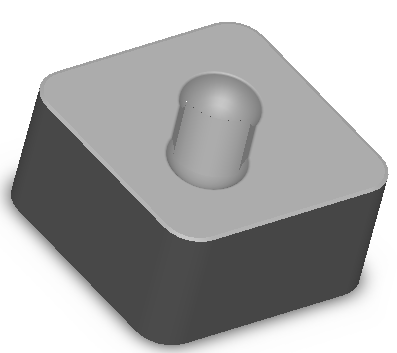

Solid CBN corner Inserts

- More flexible clamping method

- More cutting edges

- The high temperature resistance performance could be above 1000°C

- The universal clamping way can be directly clamped on existing tool holders

- The multi-standard, multispecies, can adapt more occasions processing needs

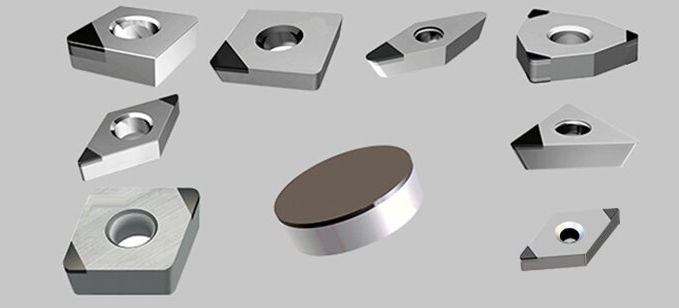

Tipped PCBN Inserts

- Be used in high precision and longer tool life cuting/machining/processing

- Diversification of the CBN inserts

- With higher hardness and better wear resistance

- Finishing, light and steady continuous cutting

- Finishing, light and interrupted cutting

By: admin

By: admin